Four-Way Diverter Conveyor Manufacturing

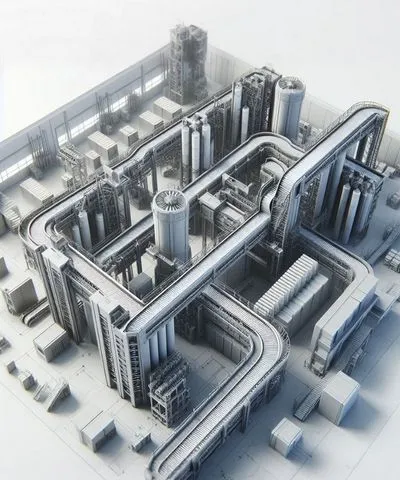

Our company specializes in industrial transport solutions and manufactures high-quality four-way diverter conveyor/sorter systems. Four-way diverter conveyors are essential equipment used in processes where materials and products need to be separated and directed into four different paths. These systems optimize material handling processes, increasing efficiency and have a wide range of applications across various industries.

Four-Way Diverter Conveyor Manufacturing Process and Quality Control

Our four-way diverter conveyor production is supported by the latest technology and meticulous quality control processes. Our production process includes the following steps:

1. Design and Planning:

– We create customized designs tailored to customer needs and projects.

– Our engineers conduct detailed planning to offer the most efficient transport solutions.

2. Material Selection:

– We use durable and long-lasting materials to ensure high performance of the conveyors.

– Materials such as steel, aluminum, and stainless steel are used.

3. Production and Assembly:

– We utilize advanced technology machines for production to ensure the conveyors are precise and reliable.

– During the assembly phase, we ensure that each component is accurately and securely assembled.

4. Quality Control:

– Our products undergo various quality control processes, including performance and durability tests.

– We guarantee that each conveyor operates smoothly and meets customer expectations.

Advantages of Four-Way Diverter Conveyors

1. High Efficiency:

– Four-way diverter conveyors ensure rapid and uninterrupted transportation and direction of materials, enhancing production line efficiency.

2. Flexibility and Customizability:

– We can produce conveyors of different sizes and features according to customer needs, providing solutions suitable for various industrial applications.

3. Durability and Longevity:

– The use of high-quality materials and robust structures ensures the conveyors are long-lasting and durable.

4. Easy Maintenance:

– Four-way diverter conveyors have low maintenance requirements, reducing operating costs.

– Maintenance operations are quick and effortless due to easily accessible parts.

5. Safety:

– Our conveyors are designed in accordance with safety standards, enhancing workplace safety and minimizing potential accidents.

Applications of Four-Way Diverter Conveyors

Our four-way diverter conveyors are widely used in various industries:

– Production and Assembly Lines: Transporting and directing products during production stages and assembly lines.

– Storage and Logistics: Regular and rapid transportation and separation of products in warehouses.

– Food and Beverage: Transportation and separation of food products under hygienic conditions.

– E-commerce and Distribution Centers: Rapid and secure transportation and separation of packages.

– Aviation and Automotive: Transporting and directing large and heavy parts.

Our company prioritizes customer satisfaction and offers high-quality and reliable four-way diverter conveyor/sorter solutions. From production to quality control, fast delivery to competitive pricing, we are ready to meet all your industrial transportation and direction needs. Contact us to find the most suitable four-way diverter conveyor solutions for your projects and benefit from the support of our expert team.