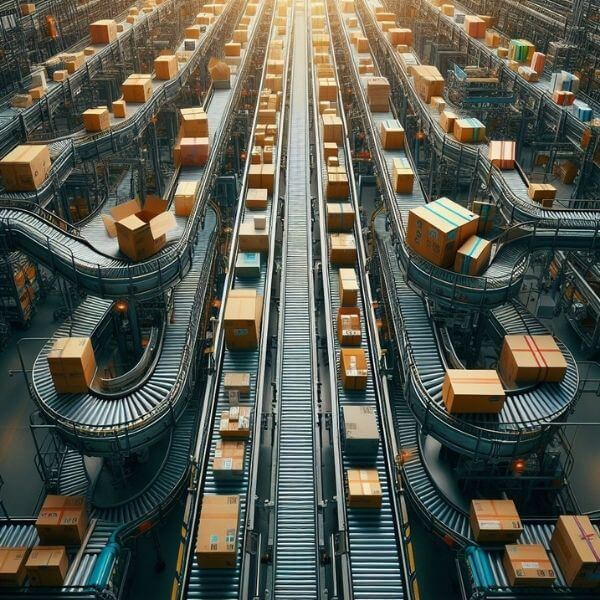

Conveyor Systems

Industrial conveyor systems play a key role for modern businesses to gain a competitive advantage and manage their processes more effectively. These systems automate critical tasks such as material handling, sorting, loading and unloading. Thus, they increase the operational efficiency of businesses and allow them to run their production lines smoothly.

Automated conveyor systems reduce the errors of manual operations by minimizing labor costs. This eliminates potential problems caused by human intervention. As a result, production processes are more reliable, consistent and of higher quality.

Increased production speed is one of the most obvious advantages of conveyor systems. By moving materials in a continuous and orderly manner, these systems minimize idle time on the production line and optimize the overall efficiency of the business. This means the ability to respond faster to customer demands and adapt faster to the market.

Distribution systems address a broad spectrum of industries. This allows for a variety of applications in different sectors and businesses. From the food industry to electronics manufacturing, logistics to automotive, conveyor systems can be adapted to meet specific needs with customizable designs.

In conclusion, conveyor systems have become one of the indispensable tools for businesses today to increase productivity, minimize errors and gain competitive advantage. These systems play an important role in optimizing industrial processes. This offers businesses a more sustainable and profitable production environment.

Conveyor System Types

1. Track Conveyors

They are efficient means of transportation, often used in industrial plants, storage areas and logistics operations. Track conveyors allow materials to be transported in an orderly manner on pallets. This allows large quantities of material to move quickly and safely. It also optimizes storage and sorting processes.

2. Spiral Conveyors

Spiral conveyors are an ideal solution for businesses that need vertical or inclined transportation. These conveyors, which are generally used in limited areas, have both vertical and horizontal movement capabilities. This allows materials to be transported in an organized and efficient manner. These features are advantageous for saving space and increasing efficiency in storage and assembly processes.

3. Wire Mesh Conveyors

These conveyors transport materials using a belt of metal wire mesh. These conveyors are generally designed for use in hot environments. They cater to a wide range of industrial applications. Their durability and resistance to high temperatures make them especially preferred in the metal industry and furnace applications.

4. Modular Conveyor Systems

It is an important technological development that offers modern and efficient solutions in industrial transportation and material management processes. These systems provide various advantages to businesses thanks to their flexible structure created by combining different modules. Here are some of the remarkable features of modular conveyor systems:

- Flexible and Customizable Design: Modular conveyor systems have the ability to adapt to different industry applications. These systems, which are created by combining modules, are designed specifically for the needs of businesses. At the same time, they are easily replaced when necessary.

- Fast Assembly and Modification: The modular design makes it possible to install and replace systems quickly. This increases the flexibility of the production line and provides the business with solutions with minimal downtime.

- Expandability According to Need: Modular conveyor systems can be easily expanded to meet business growth or changing demands. This increases the long-term sustainability of the investment.

- Various Material Handling Capabilities: Modular conveyor systems are designed to handle materials of different sizes and types. In this way, businesses get versatile solutions used in various industrial applications.

- Increasing Efficiency and Reducing Costs: Modular conveyor systems automate material handling and processing processes. This reduces labor costs and increases productivity. In addition, modular construction helps to reduce costs through energy-efficient designs.

- Environmentally Friendly Design: It focuses on minimizing environmental impact through sustainable material choices and energy-efficient technologies. This helps businesses fulfill their environmental responsibilities.

As a result, modular conveyor systems solve various challenges in industrial processes. It is also an innovative transportation technology that offers businesses flexibility, efficiency and cost benefits.

These different conveyor types support various aspects of industrial processes, providing businesses with flexibility, efficiency and reliability. By choosing the conveyor system that best suits their needs, businesses optimize their production processes and gain a competitive advantage.